GAS CARRIERS

The global need for clean energy is boosting demand for gas – and gas carriers. Bureau Veritas is using its expertise to support the development of key LNG supply chain infrastructure and innovative carriers.

THE VITAL LINK IN LNG INFRASTRUCTURE

Increasing environmental regulations have brought LNG to the forefront as a clean fuel and a step in the right direction towards reducing CO2 emissions of shipping. While safety remains first and foremost for gas carriers, a lot of attention is paid to maintaining the balance between environmental efficiency and manageable operation costs, which puts a premium on high-reliability designs. Vessels are being built to accommodate innovative technologies, and the potential for untapped gas resources in the Arctic has prompted a wave of interest in LNG tankers equipped to traverse polar waters.

HOW WE SUPPORT YOU

Bureau Veritas has a long history in gas carriers: we were the first classification society to create dedicated Rules for LNG carriers. Our expertise in gas carriers transporting both LPG and LNG, as well as their containment systems allows us to assess vessels of all types and sizes.

WHAT IS BOIL-OFF IN GAS TANKERS AND HOW CAN IT BE REDUCED?

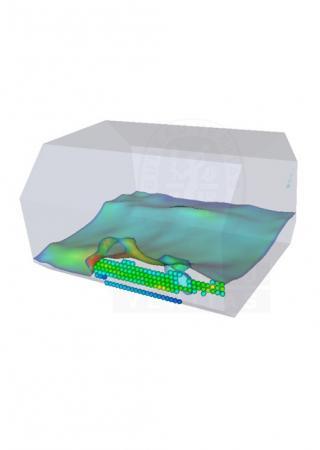

LNG carrier transport liquefied natural gas at a temperature close to vaporization (-163°C). This means that, despite tank insulation, even a small amount of heat will result in slight evaporation of the cargo, which is called “boil-off”. Bureau Veritas analyzes and issues approvals for containment systems that minimize boil-off, resulting in improved performance.

Photo credits ©DSME, Exmar, DYNAGAS, GTT, Sirius Shipping